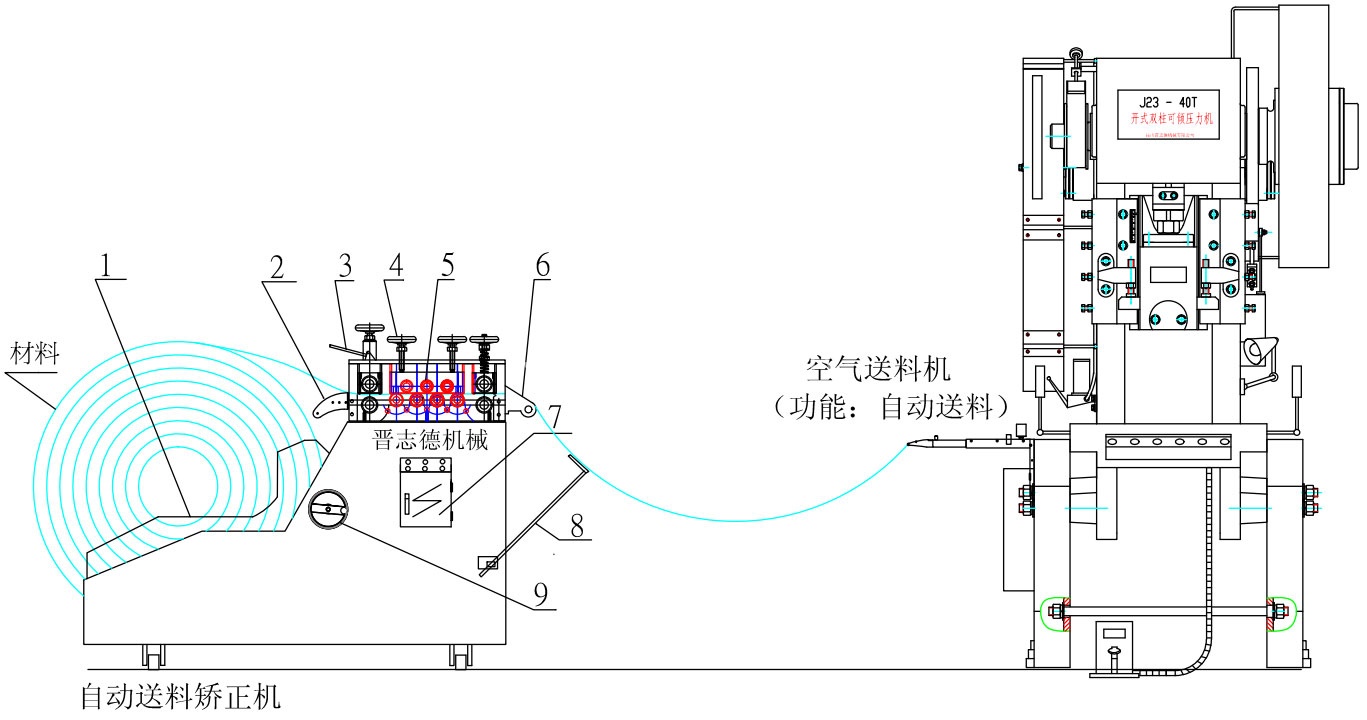

Air Feeder

Features:

● Material thickness:0-3.0mm

● The most economical punch press Feeder

● The best price feeder machine

● simple operate

● easy for metal feeding

● Smallest volume

● suitable for many kinds of punching machine

● FOB port:SHANGHAI or other port

Product Detail

Application Video

Product Tags

Air Feeder Specification :

| Model | AF-1C | AF-2C | AF-3C | AF-4C | AF-5C | AF-6C | AF-7C | AF-8C | AF-10C |

| Max.feeding width(mm) | 50 | 65 | 80 | 100 | 150 | 200 | 250 | 300 | 400 |

| Max.feeding length(mm) | 50 | 80 | 80 | 130 | 150 | 200 | 250 | 300 | 400 |

| Material thickness(mm) | 0.5 | 0.8 | 1.2 | 1.5 | 2 | 2 | 2.5 | 2.5 | 3 |

| Pneumatic pressure | 4.5 | 4.5 | 4.5 | 4.5 | 4.5 | 4.5 | 4.5 | 4.5 | 4.5 |

| Max.feeding S.P.M | 250 | 200 | 180 | 130 | 100 | 70 | 50 | 45 | 30 |

| Fixed clamp friction(kg) | 10 | 27 | 40 | 55 | 78 | 78 | 90 | 100 | 119 |

| Moving clamp friction | 30 | 49 | 65.5 | 72.5 | 144.5 | 169 | 200 | 217 | 245 |

| Tension force(kg) | 14 | 16.5 | 19.5 | 25.5 | 41 | 41 | 67 | 74 | 85 |

| Air consumption(L/mm) | 26.5 | 38.5 | 47 | 58.6 | 100.5 | 108.5 | 152 | 162.5 | 182.5 |

| Weight(kg) | 8.8 | 9.6 | 12.8 | 19.6 | 38.4 | 52.4 | 80 | 96 | 178 |

Air Feeder Features:

● The central hole of the main structure is by lapped finishing first and then electroplating so as to better ensure its roundness and straightness,which thus enables the core shaft to run smoothly.

● After processed,the main structure goes through anti-corrosive treatment,and then it is cleaned through ultrasonic wave before assembled so as to guarantee trouble-free when processing leftover materials.

● The exchangeable reversal valve is constructed large circular angle and its internal bore goes through mirror polishing treatment so as to greatly improve feeder’s loading speed and the life span of sealing ring.

● All the sealing parts are introduced from japan.

● Two-position three-way valve structure is adopted in the new floating lever,and thus gas-leaking problem is solved.

● Two units of pneumatic cushions are adopted to efficiently reduce vibration and noise.

● The guiding rail is processed through hard chrome plating finish after going high tensile steel heating process.the connection between mobile part and guiding rail goes through accurate grinding so as to make machine moving and its motion flexible and stable.

● All screws are fixed with high-strength oxygen pressed rubber so as to avoid loosening from vibration,yielding good dealing capability.

● Air feeder features compact conformation,high accuracy,high speed,and a good combination of beauty and application.all machines are tested strictly.